Innovative technologies, individual image processing solutions, comprehensive service

We offer our customers a broad portfolio of high-quality solutions for image processing and identification, such as vision sensors, vision systems, stationary and mobile code readers, verification systems, lenses and lighting from leading manufacturers and brands at optimal conditions for them.

In doing so, we take over the complete communication with manufacturers and suppliers, carry out necessary feasibility studies and, together with our partners, also take care of the integration and the subsequent validation and documentation of the desired applications. In this way, our customers receive a competent all-round service from a single source, tailored to their individual project goals and framework conditions. With our help, our customers save resources such as time and costs and achieve demonstrable success with high efficiency.

Our services

Numerous fields of application

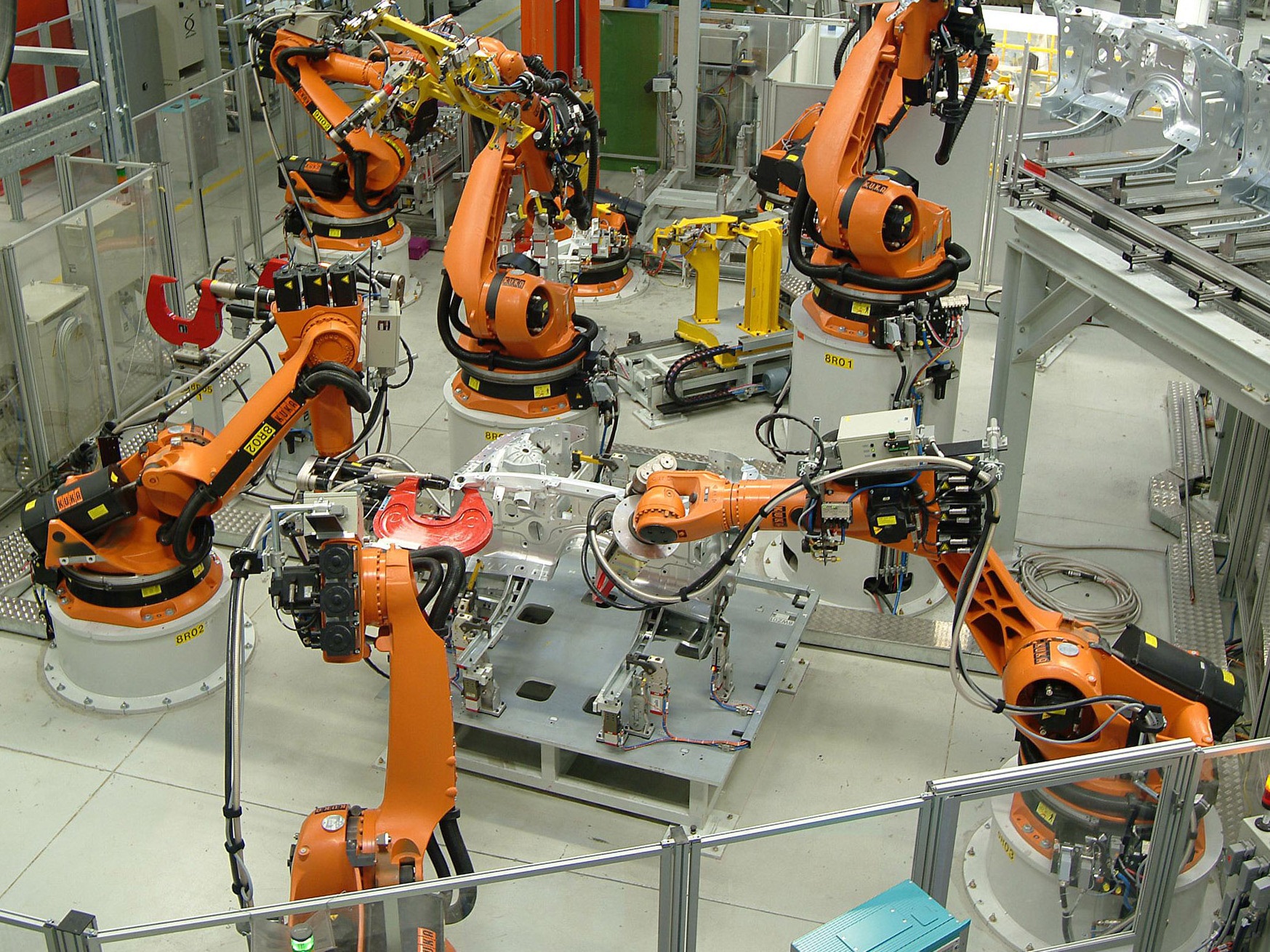

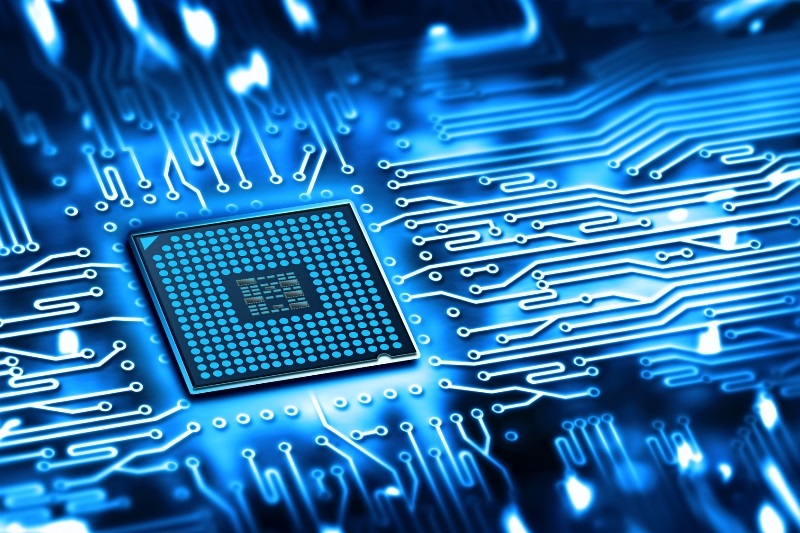

Industrial identification and image processing systems are used in a wide range of industries. Here are some examples of application areas.

Automotive Industry

Pharmaceutical Industry

Consumer Goods

Logistics

Automation Equipment

Electrical Industry

Food & Beverage Industry

Tobacco

Whether quality control, defect detection, traceability or further process optimization: Your productivity and quality increase is our concern. Contact us and let us implement your automation projects together.