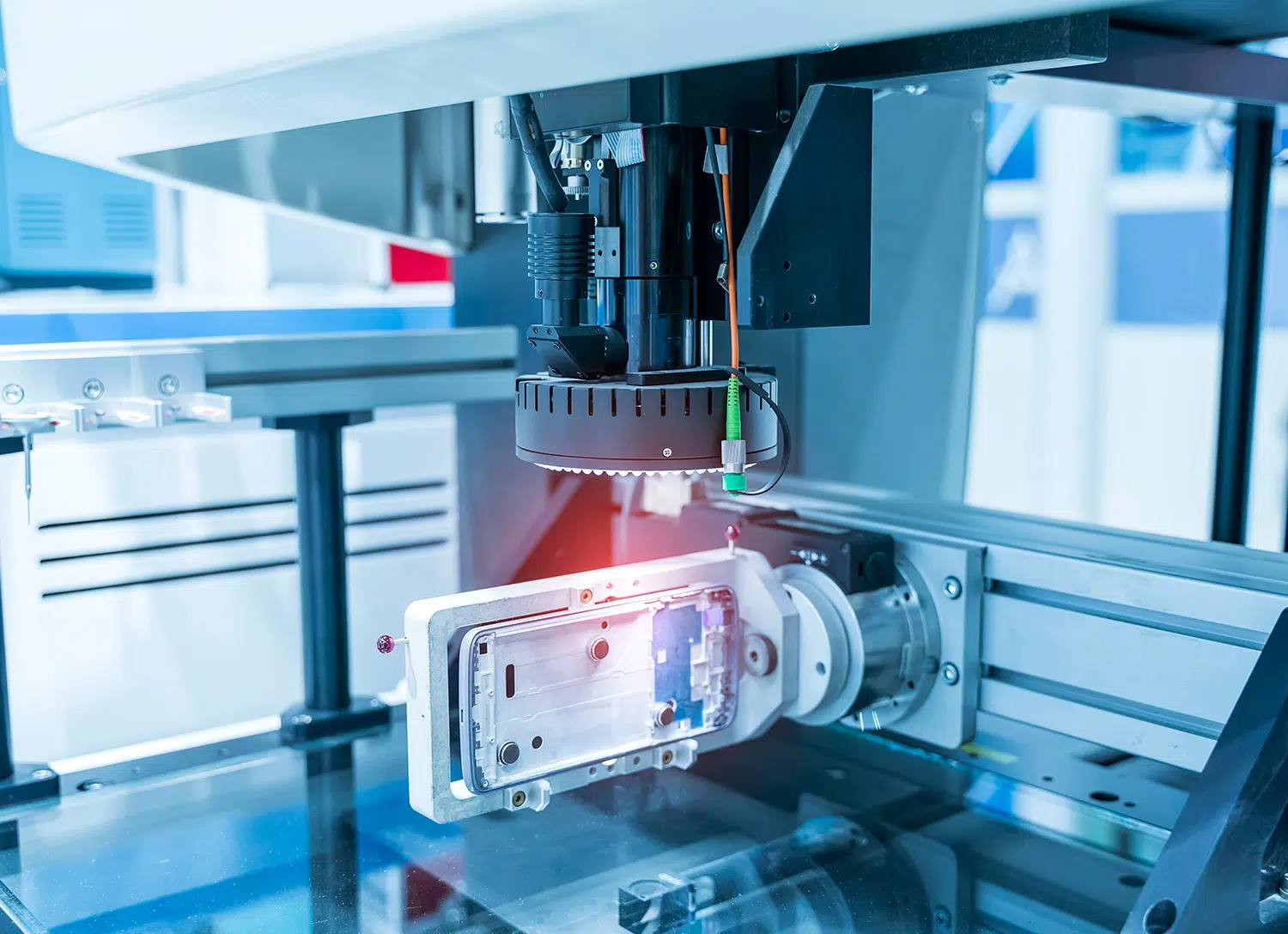

Image processing systems for complex applications

Especially in complex applications where defect detection on difficult surfaces or accurate measurements are required, intelligent machine vision systems are indispensable for complex applications.

Recognized manufacturers of machine vision solutions such as Cognex, Keyence or Zebra carry comprehensive portfolios with powerful machine vision systems. As an independent partner, GK VISION GmbH – VISIONTECHNIK works together with the above-mentioned manufacturers, among others, and supports you in finding the best possible solution for your application and within the scope of your requirements.

In-Sight 3800 – Cognex

In-Sight 3800 – Automation at the highest level for your manufacturing applications

The In-Sight 3800 from Cognex is a powerful all-in-one vision system. The successor to the In-Sight 7000 series, the In-Sight 3800 is an advanced vision system that solves a wide range of manufacturing applications, including defect detection, assembly verification, character recognition, and AI-based classification.

The In-Sight 3800 vision system is equipped with rule-based and AI-based vision technology and features high speed, high resolution and high flexibility.

The processing speed of the In-Sight 3800 is twice that of previous vision systems. With fast tools and edge learning, you can maximize throughput and optimize your manufacturing processes.

Thanks to high-resolution images and innovative technologies, even the finest defects can be detected, resulting in accurate and reliable inspection results.

Built-in edge learning tools enable users to leverage artificial intelligence and achieve reliable automation using simple examples. The tools cover a wide range of applications, from presence and absence detection to optical character recognition. In addition to edge learning, the In-Sight 3800 also offers a comprehensive set of rule-based tools that can be used individually or in combination to tackle challenging jobs.

The modular hardware of the In-Sight 3800 allows easy adaptation to different requirements and conditions, enabling smooth handling of various applications.

- Image sensor: The In-Sight 3800 is available in several model types that feature different image sensors, including 8-bit grayscale and 24-bit color. Sensor types range from 1/2.3-inch CMOS to 2/3-inch CMOS with global shutter for precise image capture.

- Maximum Image Resolution: Depending on the model variant, the In-Sight 3800 offers a maximum image resolution of up to 2448 x 2048 pixels, providing high-resolution, high-contrast images for accurate defect detection.

- Electronic shutter speed: The In-Sight 3800’s adjustable electronic shutter speed allows for optimal adaptation to different tasks and environments.

- Development environments: The vision system uses In-Sight Vision Suite software with two development environments: EasyBuilder® and Spreadsheet. These provide flexible development and customization options for simple and complex applications.

- Illumination: Provides integrated multi-color illumination (RGBW and IR), optimizing image formation and maximizing contrast and illumination.

The In-Sight 3800 can be used in a variety of industries, including:

- Automotive industry and electric vehicles: EV pouch cell inspection, connecting rod identification, seal quality inspection, O-ring detection, spark plug measurement, tire identification and more.

- Consumer Goods Packaging: Reading labels on detergent bottles, inspecting makeup pallets, robotic guidance for pick and place, soap fragrance classification, and more.

- Electronics: counting pins, checking for completeness and correctness of electronic components, and more.

In-Sight 7000 – Cognex

Precision combined with flexibility: In-Sight 7000 from Cognex

The Cognex In-Sight 7000 Series is a full-featured vision system that excels in precision and flexibility. With accurate inspections, even at high production line speeds, this series offers an ideal solution for demanding industrial applications. Thanks to its compact design, it easily fits into environments with limited space and allows for easy adaptation to various on-site application requirements. This series has many features and benefits that make it a powerful tool for a wide range of applications.

The In-Sight 7000 Series is a full-featured vision system that performs accurate inspections even at high production line speeds. Its compact size allows it to fit easily on lines with limited space, and its modular design makes it easy to adapt to your application requirements in the field. In addition to internal and external illumination supply/control options, the In-Sight 7000 Series features a highly visible pass/fail LED indicator ring around the camera housing, making it easy to see inspection status no matter where the system is installed.

- Accurate inspections at high speed: The In-Sight 7000 Series offers extremely fast acquisition rates and industry-leading image processing tools, including PatMax RedLine, SurfaceFX, OCRMax, PowerGrid, Hotbars and Color Tools (in color models only). This allows the system to quickly locate parts and accurately perform the required inspections without compromising speed.

- Versatile design: Featuring Flexible Image Technology (FIT™), the In-Sight 7000 Series offers a wide range of field-customizable illuminators and lenses. This allows the system to be precisely tailored to the specific requirements of your application, optimizing image capture and minimizing the need for expensive external illumination.

- Model diversity: The series is available as black-and-white and color models with resolutions from VGA to 5 MP. There are different model types, from the basic In-Sight 7500 to the fully featured 7600, 7800 and 7900 models, allowing customers to select the right model to suit their requirements.

- Easy integration: The In-Sight 7000 Series is equipped with complete vision tools that include PatMax, PowerGrid and Hotbars. This simplifies the programming and implementation of optical inspection applications and ensures reliable implementation of your applications.

- Industrial protocols: The In-Sight 7000 series supports various industrial protocols such as OPC UA, EtherNet/IP, PROFINET Class B, Modbus TCP and more. Thanks to the IP67 protection rating, the series is well protected in demanding environments.

The versatility of the In-Sight 7000 Series makes it ideal for inspecting automotive parts, consumer electronics, consumer products and automation in industries such as food and beverage, pharmaceutical, aerospace, semiconductor and solar.

In-Sight 8000 – Cognex

Performance in an Ultra-Compact Package – The In-Sight 8000 Series from Cognex

With the In-Sight 8000 Series, Cognex has launched the smallest stand-alone solution that can be integrated into small and tight spaces as a stand-alone full-function camera.

With this world’s smallest stand-alone vision system, you can optimally integrate robots and production lines even in the tightest spaces. The In-Sight 8000 Series is ideal for a variety of vision applications, including inspection, matching/measuring, guiding/aligning, OCR/OCV and barcode reading. With its powerful features, it enables precise inspection, identification and guidance of parts.

- Ultra-compact design: The In-Sight 8000 Series features compact dimensions of only 35 mm x 32 mm x 76 mm.

- Versatile models: The series offers a wide range of monochrome and color models in resolutions from 0.3 MP to 5 MP. These models support Gigabit Ethernet for high-speed connections and offer fast acquisition rates to meet a variety of imaging needs.

- Fast communication interfaces: Thanks to Power over Ethernet (PoE), the In-Sight 8000 models can be equipped with powerful image processing tools and operated via a Gigabit Ethernet connection. This enables very fast image capture and transmission.

- Precise pattern matching with RedLine: The series uses PatMax RedLine to perform extremely fast pattern matching and reduce cycle times without compromising inspection accuracy. This enables the In-Sight 8000 Series to deliver outstanding performance in demanding applications.

The In-Sight 8000 Series has applications in a variety of industries, including inspection of assembly defects, surface defects and damage, measurement of critical dimensions, part guidance and alignment, OCR/OCV reading, barcode reading and much more.

The ultra-compact design and high performance of the In-Sight 8000 series make it the ideal solution for demanding vision requirements in areas such as the electronics, automotive, medical and pharmaceutical industries.

In-Sight 9000 – Cognex

In-Sight 9000 Series from Cognex: highest resolution and robust performance

The In-Sight 9000 Series from Cognex is a rugged line of standalone vision systems with extremely high resolution. With the ability to capture and process detailed images, the In-Sight 9000 Series provides accurate part location, measurement and inspection over large areas, even at greater distances.

The In-Sight 9000 Series enables a single camera solution for applications with large objects or parts. This reduces complexity and calibration requirements and saves costs.

With the ability to capture both moving and stationary objects, the In-Sight 9000 Series can be used efficiently in demanding environments. Whether inspecting product quality, measuring critical dimensions or detecting surface defects, the In-Sight 9000 Series provides reliable and accurate solutions for a wide range of vision applications.

This versatile series offers a single-camera solution for multi-camera applications that is more cost-effective, less complex and ideal for production lines with limited space.

- High resolution: with image types of 12 MP (4096 x 3000) and 32 MP (2048 x 16384), the series offers exceptional image resolution. It captures a large field of view to inspect large objects while maintaining the finest details.

- Rugged performance: The In-Sight 9000 Series is capable of capturing constantly moving or stationary objects with line scan and area scan image capture options. The system’s rugged design and IP67 rating protect it from liquids and dust, making it suitable for harsh environments.

- Versatile image processing tools: The series offers a comprehensive range of image processing tools, including blob tools, edge and edge inspection tools, and PatMax and PatMax RedLine for precise localization and pattern recognition.

The In-Sight 9000 series is widely used in various industries. Its high resolution and precision make it ideal for applications that require detailed part location, measurement and inspection over large areas. It is useful in the automotive, electronics, food and beverage, packaging and many other industries.

In-Sight D900 – Cognex

In-Sight D900 from Cognex: Deep learning automation solution for highly complex applications

The Cognex In-Sight D900 vision system is an advanced solution for difficult OCR, assembly verification and defect detection applications. It automates complex tasks that traditional rule-based vision systems struggle to handle, and achieves reliable, fast and consistent results that would not be possible with human inspection.

The In-Sight D900 series offers a full suite of edge learning and deep learning tools that enable a wide range of applications. Using artificial intelligence (AI), complex features and objects can be reliably detected and inspected in a user-defined layout to ensure parts and sets have been assembled correctly.

One of the most notable features of the In-Sight D900 is its ability to perform optical character recognition (OCR) of difficult characters and text in just minutes. The system recognizes highly deformed, skewed and poorly etched codes using a pre-trained font library, dramatically reducing development time. In addition, the OCR tool can be effortlessly retrained for application-specific characters.

- Edge learning and deep learning: The In-Sight D900 series uses edge learning and deep learning technologies to recognize complex features and objects and perform precise tasks such as optical character recognition (OCR), assembly verification, and defect detection.

- Full suite of AI tools: The series includes a comprehensive suite of AI tools to detect highly deformed, skewed and poorly etched codes, perform fast and accurate assembly checks, and detect and analyze subtle defects.

- No PC required: Editing is done directly on the device without the need for a separate PC. This simplifies application deployment and gives non-programmers access to the power of artificial intelligence (AI).

- Fast setup for OCR applications: Optical character recognition (OCR) enables difficult characters and text to be read in just a few milliseconds. With pre-trained font libraries, development time can be drastically reduced.

- Precise assembly checks: The In-Sight D900 Series can reliably detect complex features and objects and verify that parts and sets have been assembled correctly. The system can detect a variety of components even at different angles and sizes.

- Detection of subtle defects: The integrated detection tool is ideal for finding anomalies on complex parts and surfaces, even in situations where the appearance of the defects is unpredictable.

The In-Sight D900 series finds application in various demanding image processing applications where conventional rule-based systems reach their limits. It is widely used for:

- Optical character recognition (OCR) of difficult codes and texts

- Precise assembly checks of complex components and sets

- Detection and analysis of subtle defects on parts and surfaces

In sectors such as automotive, electronics, solar and others where high precision and reliability are required, the In-Sight D900 series offers a revolutionary solution for machine vision using artificial intelligence.

VS70 – Zebra

VS70 from Zebra – The customizable solution for efficient image processing

Zebra’s VS70 is an intelligent machine vision camera that is fully customizable to meet the unique needs of quality inspection.

The intelligent camera enables precise defect detection, resulting in reduced scrap and errors. With external illumination compatibility and high-quality lenses, the VS70 captures accurate and detailed images for reliable analysis. With the ability to add advanced tools through software upgrades, the VS70 can support future needs.

- Customizability: The VS70 is fully customizable and can be equipped with various lenses, including wide-angle lenses, zoom lenses, and specialty lenses. This allows it to adapt optimally to your specific application and environment.

- External illumination compatibility: The camera is compatible with virtually any external illumination, allowing highly accurate and detailed images to be captured even in low contrast or difficult surface conditions.

- Reliable process validation: The VS70 helps manufacturers achieve consistent quality and quantity specifications by validating assembly and tracking information.

- Aurora™ Software: The intuitive Aurora™ software platform simplifies configuration, deployment and operation of the VS70 and other Zebra smart cameras. Exclusive Zebra features such as ImagePerfect Setup and Feasibility Wizards reduce labor and costs.

The VS70 has a wide range of applications in industry, especially in the areas of quality control, inspection and tracking. It is ideal for manufacturers who need a reliable and customizable machine vision solution to ensure the quality of their products and optimize the production process.

CV-X series from Keyence: a vision system for numerous applications

Keyence has launched the CV-X series, an innovative and very user-friendly platform that can handle almost any inspection requirement with a choice of eight different controllers each equipped with new algorithms, a variety of area scan camera models in the range of up to 64 MP resolution, and various lighting options.

Whether reading codes, defect inspection, feature inspection or measurements, the CV-X vision system combines speed with precision and ensures high quality while maintaining efficiency.

Thanks to the newly developed LumiTrax illumination system from Keyence, known environmental influences such as different surface structures, ambient light and moving inspection objects can be eliminated during image acquisition. Multiple images of the inspection object are captured simultaneously, each with a differently configured illumination, to determine patterns and inconsistencies in detail and provide reliable inspection results.

With its ability to accurately image parts on the production line, the CV-X increases efficiency and ensures quality in a variety of industries, including automotive, electronics, medical, food and packaging. The vision system is particularly suited for processes that require inspection of high-volume parts. With applications such as defect detection, surface inspection, part and feature inspection, assembly verification, measurement and code reading, the CV-X enables reliable and smooth production flow.

The CV-X model series can further communicate with a wide range of robots and provides an easy connection between robots and machine vision thanks to automatic calibration.

- High-speed cameras: The CV-X is equipped with high-speed cameras that enable fast and precise image acquisition. This results in efficient inspection of parts at high speed.

- Adaptability: The CVX is an extremely flexible system that can adapt to the specific requirements of different manufacturing processes. Whether it’s a wide-angle lens for large parts or a special lens for precise measurements, the CVX can handle any inspection task.

- Quality assurance: Through accurate surface inspection and defect detection, the CV-X ensures consistent, high-quality production, which reduces scrap rates.

- Future-proof: Thanks to simple software upgrades, the CV-X can be easily adapted to changing business requirements without having to buy a new device.

- Automotive industry: parts inspection, defect detection, quality inspection

- Electronics industry: assembly testing, code reading, measurements

- Medical industry: surface inspection, parts and features inspection, quality control

- Food industry: quality inspection, code reading, defect detection

- Packaging industry: packaging verification, code reading, defect detection

XG series from Keyence – High-precision and flexible high-end image processing for demanding applications

Another model series is the XG image processing series for high-end applications from Keyence. This series is specially designed for very demanding image processing applications and advanced users.

The platform supports all Keyence cameras – from line scan and 3D cameras to 64 MP resolution color cameras – and enables flexible flowchart-style programming using XG-X VisionEditor software. For example, inspection applications and simulations can be easily developed and user interfaces created. Like the CV-X series, XG is equipped with the powerful ShapeTrax 3 search tool, which automatically extracts object features during search and delivers high-precision search performance.

- Universal camera support: The XG series is compatible with all Keyence cameras, including 0.47-megapixel, 2-megapixel, 5-megapixel, and 21-megapixel cameras.

- ShapeTrax™ 3 search tool: The integrated ShapeTrax™ 3 search tool optimizes inspection stability and enables automatic configuration of contour settings.

- High-resolution image capture: The 9.44-megapixel CMOS image capture sensor enables high-resolution images for precise inspections.

- Inspection of the external appearance of coils and their dimensions

- Camera inspection of solder joints and crimp connections

- Inspection of plastic injection molded parts

- Measurement applications requiring multispectral 3D imaging