Advantages of machine vision for automation and quality assurance

State-of-the-art machine vision systems play an indispensable role in numerous industries, such as medicine, pharmaceuticals, food, automotive and logistics. They ensure high productivity, quality and cost efficiency in work and production processes.

Intelligent vision systems are essential for a wide range of applications such as inspection, defect detection, measurement, machine guidance, OCR (Optical Character Recognition) and barcode reading. They enable precise and reliable solutions for a wide variety of tasks such as:

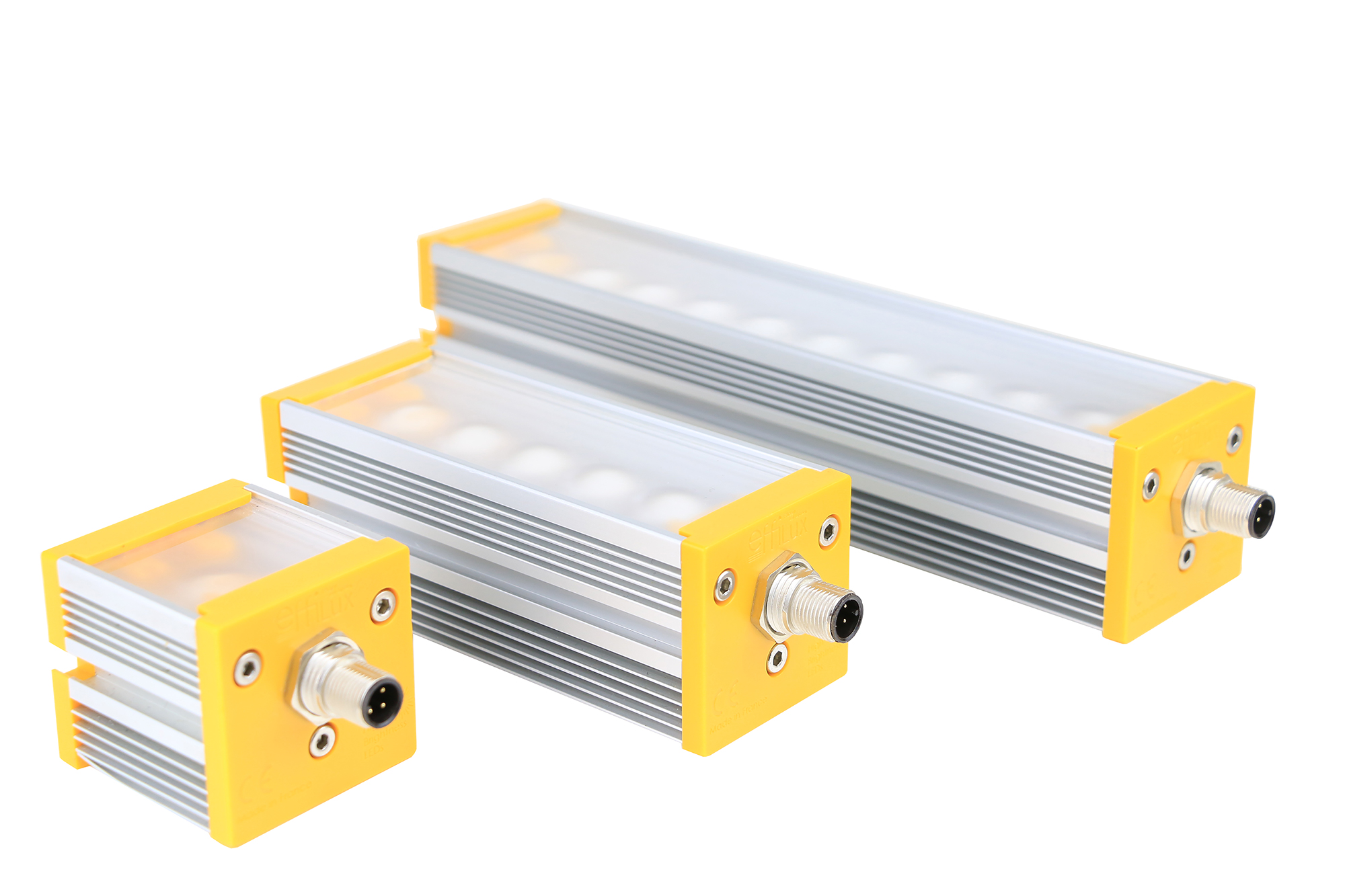

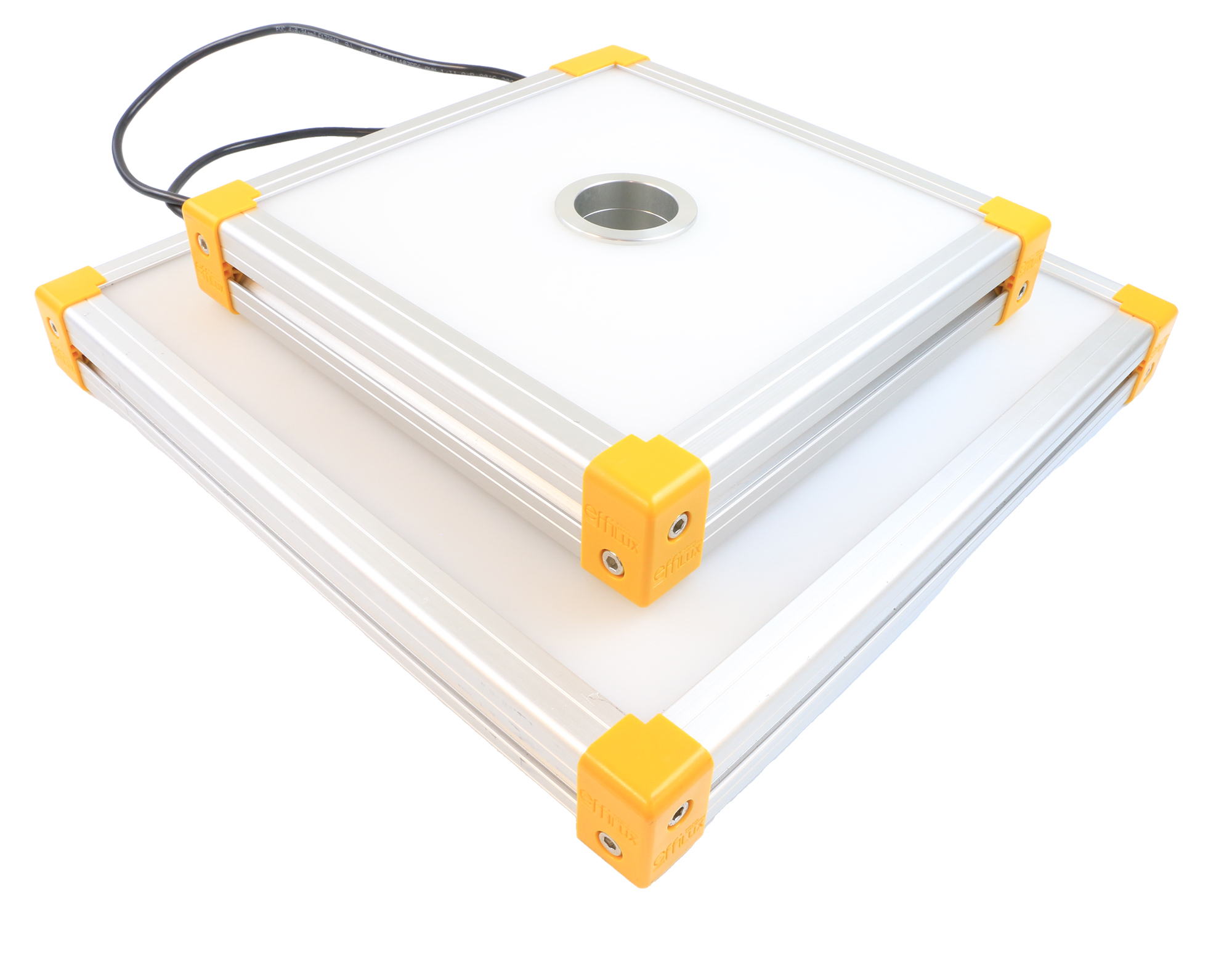

Product Highlights

Our product highlights from renowned manufacturers offer a wide range of benefits for industrial automation and quality assurance. Combining sophisticated cameras and advanced software, these systems ensure accurate and reliable results every time, helping you increase productivity, reduce waste and improve the quality of your products.

We know that choosing the right vision system is an important decision. At GK VISION GmbH – VISIONTECHNIK, we specialize in providing you with customized machine vision systems that meet your requirements in the best possible way. Our experts are ready to assist you in the selection, implementation and use of the selected products. We offer comprehensive consulting, training and technical support to ensure you get the most out of your investment.