Industrial Image Processing – Machine Vision for Quality & Automation

As an independent system integrator with many years of experience, VISIONTECHNIK combines state-of-the-art image processing technology with tailored consulting to provide the optimal solution for every industrial challenge.

In addition to our standard range, we offer many products on request – individually tailored to your specific applications and requirements. For further products or custom solutions, simply contact us via our contact form.

Industrial image processing combines precision with intelligence

Application Areas of Industrial Image Processing

Industrial image processing is used across nearly all industries, offering a wide range of applications. Wherever automated visual inspection or measurement is required, it ensures reliable results — 24/7 and at high speed. Whether in electronics manufacturing, the automotive industry, food production, or pharmaceuticals, camera-based inspection technology detects defects, counts objects, reads codes, and guarantees comprehensive quality control. The following examples illustrate how broad and versatile the field of industrial image processing is in practice.

Quality Control and Inspection Technology

Machine vision products now handle quality control tasks that once had to be performed manually. They inspect workpieces for dimensional accuracy, detect surface defects, and verify the completeness of assemblies — all with objective precision. Thanks to industrial image processing, 100% inspections can be carried out efficiently: every part is examined for defects within milliseconds. This improves product quality and reduces waste, as faulty components are identified and removed early in the process. In addition, automated inspection technology provides complete documentation of all test results, ensuring traceability and quality verification throughout production.

Identification and Object Recognition

Industrial image processing can read barcodes and QR codes, recognize printed text (OCR), or identify parts based on shapes and visual features. This ensures in logistics and production that every product is in the right place at the right time (track & trace). Completeness checks — for example, verifying whether all components in an assembly are present — are reliably performed through camera-based object recognition. The machines “understand” what they see: from detecting a part’s position to sorting various products according to optical characteristics. This increases process reliability and enables seamless monitoring of complex workflows.

Robotics and Industry 4.0

Robot vision systems give robots the ability to perceive their environment visually. This enables them to pick unsorted objects from bins (bin picking), position components with high precision, and respond flexibly to variations in the production flow. The combination of image processing and robotics is a key driver of the smart factory concept within Industry 4.0. Cameras act as sensors, delivering real-time information to machines and control systems. These vision systems are networked and integrated into automation solutions, creating highly flexible, self-optimizing production environments. Manufacturers benefit from reduced downtime, as visual monitoring detects deviations early and allows immediate corrective action.

Industrial Image Processing –

Components and Technologies

Industrial Cameras and Lenses

Choosing the right camera is fundamental for every image processing solution. Industrial cameras differ in resolution, frame rate, and sensor type (CCD or CMOS) and are used as area scan, line scan, or 3D cameras depending on the application. Equally important is the optics: lenses must match the sensor and inspection task to ensure the test object is captured sharply and without distortion. Specialized industrial lenses — such as telecentric optics — enable accurate, scale-correct measurements, while wide-angle or macro lenses meet other specific requirements. Modern camera technologies combined with high-quality optics form the foundation for reliable results in industrial image processing — because only a clear, detailed image allows the evaluation software to deliver precise outcomes.

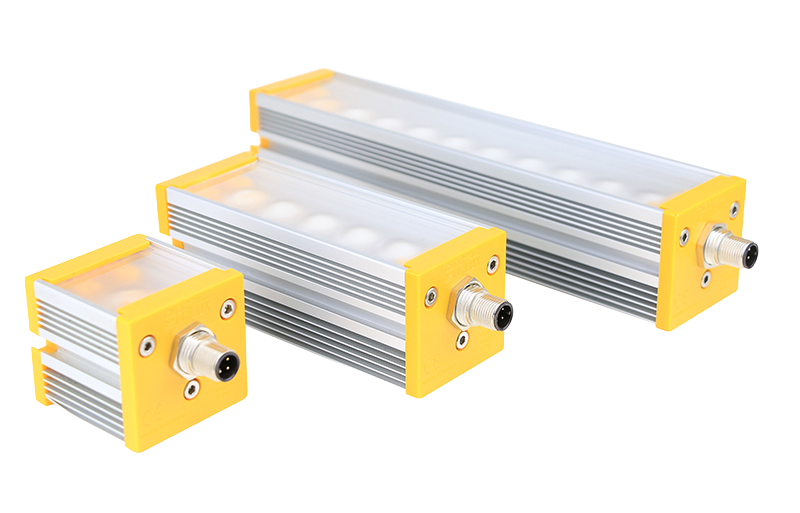

Lighting in Image Processing

Without optimal lighting, even the best camera is of little use. In industrial image processing, lighting is a decisive factor in making features visible. Different types of illumination are used: transmitted light highlights contours, reflected light with ring or spot illumination emphasizes surface characteristics, and diffuse dome lighting reduces reflections. The choice of light color (such as infrared, red, or blue) and uniform illumination increase contrast exactly where it is needed. Professional vision systems often use LED lighting that can be precisely controlled in brightness and timing. Carefully planned lighting technology ensures that the camera always receives optimal image information — providing the foundation for reliable inspection results.

Hardware and Software

The captured image data must be evaluated in real time — this is where powerful hardware and intelligent software come into play. Industrial PCs with frame grabbers, specialized vision controllers, or increasingly compact embedded systems handle image processing directly at the machine. This image processing hardware is designed to manage large amounts of data quickly and reliably, even in harsh industrial environments. Equally important is the software: image processing software uses algorithms to detect features, identify deviations, or take measurements. Alongside traditional rule-based methods, artificial intelligence is becoming increasingly prevalent. With machine learning techniques — such as deep learning — even complex patterns or previously unknown defects can be learned and recognized from sample data.

Advantages and new Developments in Industrial Image Processing

- Quality assurance: Defective products are reliably detected and removed before leaving the factory.

- Automated visual inspections operate fatigue-free around the clock, delivering objective and reproducible results – unlike manual inspections, which can be subjective and error-prone.

- Furthermore, vision systems increase efficiency by enabling high inspection speeds and freeing personnel for more demanding tasks.

Current technological developments – from artificial intelligence to networked Industry 4.0 systems – are continually expanding the scope of image processing. Companies that invest in this key technology gain an innovation advantage while simultaneously reducing costs through less waste and minimized downtime.

Improving Quality and Efficiency

AI and Deep Learning in Image Processing

A major trend in industrial image processing is the use of artificial intelligence (AI) and deep learning algorithms. AI systems can independently learn from large amounts of data to recognize visual patterns and detect defects — without requiring every inspection feature to be explicitly programmed. This opens up new possibilities, particularly in surface inspection: even complex or hard-to-describe defects (such as paint flaws or fabric irregularities) can be reliably detected by a trained deep learning model. The combination of classical image processing and AI results in more robust inspection systems that can adapt to changing conditions. VISIONTECHNIK leverages these forward-looking technologies to provide customers with solutions that keep pace with technological progress and deliver outstanding results, even for complex inspection tasks.

Networked Vision Systems

In the context of Industry 4.0, image processing systems are becoming increasingly networked and intelligently integrated into production environments. This means that cameras and inspection devices communicate with other machines and IT systems along the value chain. For example, a vision system can report quality deviations to the control center in real time, triggering automatic corrective actions. Thanks to standardized interfaces (such as OPC UA), image processing solutions can be seamlessly integrated into factory IT infrastructures.

Embedded vision components are also gaining importance: more and more cameras with their own processing units are being built directly into machines to make decentralized, real-time decisions. This connectivity and distributed intelligence lead to more flexible and efficient production. For your company, this translates into higher transparency, faster response times, and an overall future-proof manufacturing process — with industrial image processing serving as the core of automation.